Belonging category: Asphalt Fibers and Additives

Release time: 08-07-2023

Click count: 791

Product Details

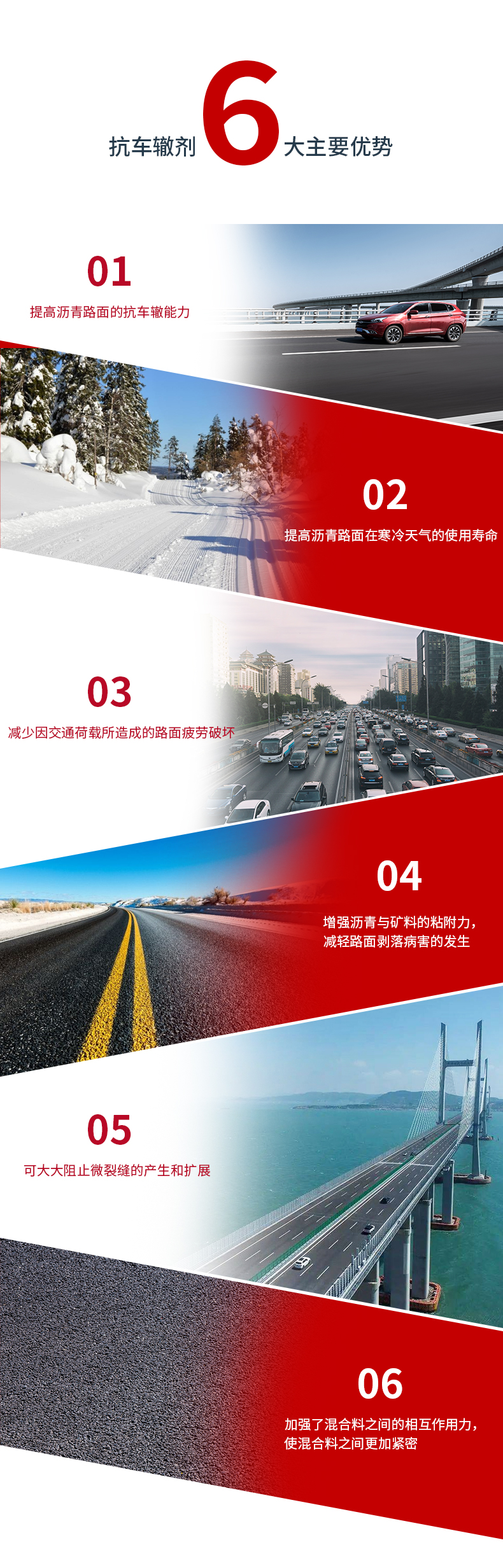

Anti-rutting agent 抗车辙剂

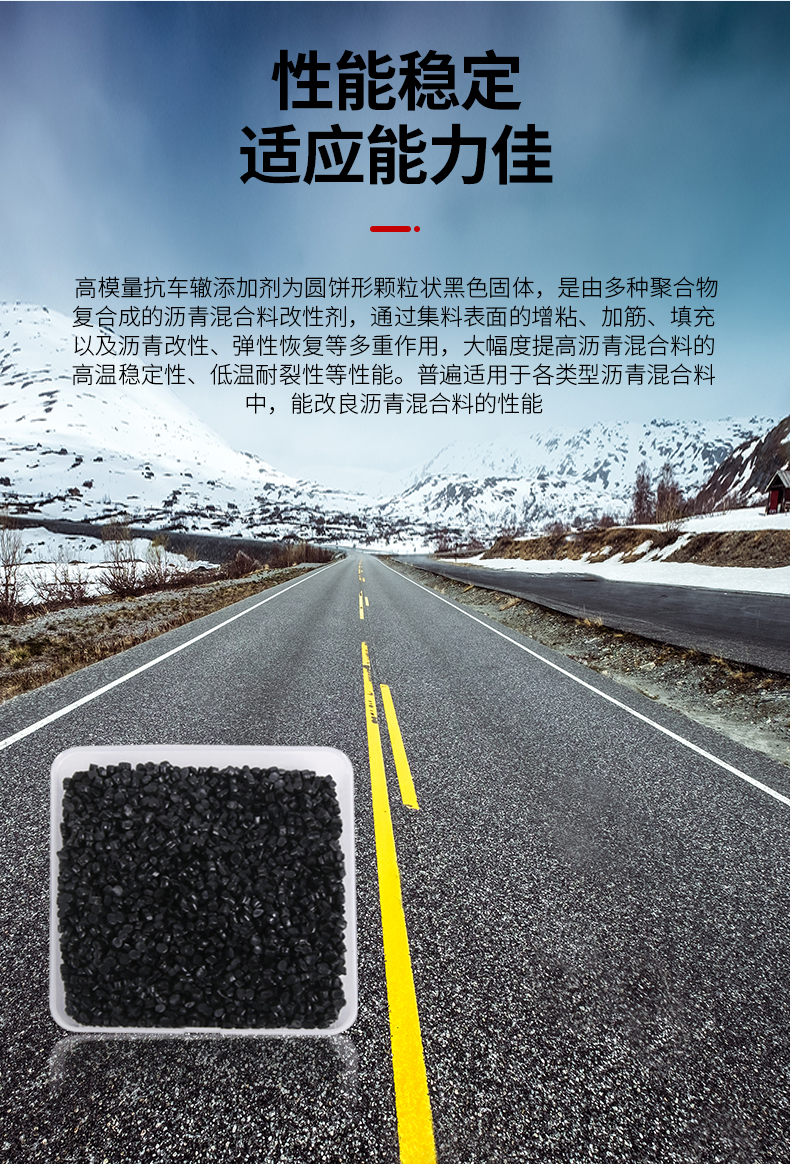

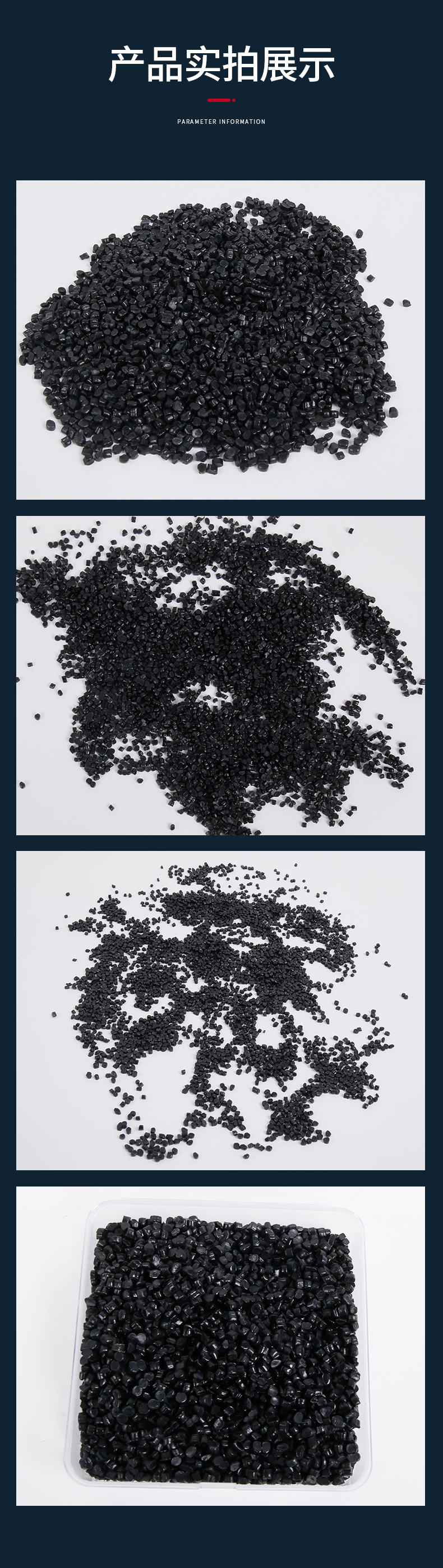

The anti-rutting additive is a round, granular black solid, and is an asphalt mixture modifier composed of a variety of polymers. Through multiple functions such as viscosity enhancement, reinforcement, filling on the aggregate surface, asphalt modification, and elastic recovery, it greatly improves the high temperature stability and low temperature crack resistance of asphalt mixtures.

It is widely used in various types of asphalt mixtures and can improve the performance of asphalt mixtures.

Parameters

Physical properties: dark solid granules

Particle size ≤4mm

Density: 0.90~1.05x1000 Kg/m3

Softening point: 135~150℃

Melt index: 7~10g/10min

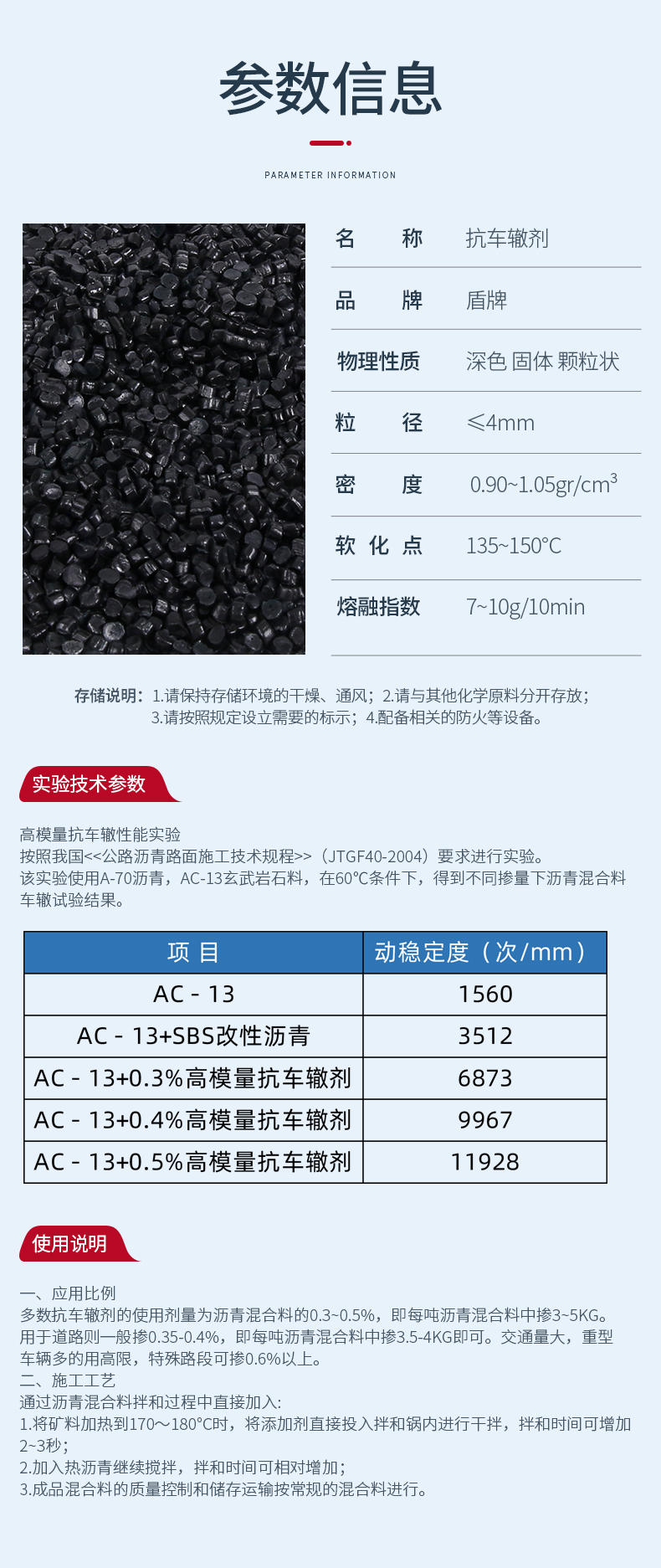

Experimental technical parameters

The high modulus anti-rutting performance test was conducted in accordance with the requirements of China's "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004). The experiment used A-70 asphalt and AC-13 basalt stone, and obtained the rutting test results of asphalt mixtures at different dosages at 60°C.

| Dynamic stability (times/mm) | |

AC-13 | 1560 |

| AC-13+SBS modified asphalt | 3512 |

| AC-13+0.3% high modulus anti-rutting agent | 6873 |

| AC-13+0.4% high modulus anti-rutting agent | 9967 |

| AC-13+0.5% high modulus anti-rutting agent | 11928 |

Usage instructions

Application ratio The dosage of most anti-rutting agents is 0.3-0.5% of the asphalt mixture. For roads, it is generally mixed with 0.35-0.4%. The upper limit is used in areas with heavy traffic and heavy vehicles, and 0.6-0.8% can be added in special sections.

Construction process

Directly add during the mixing process of asphalt mixture:

1. When the mineral material is heated to 170-180℃, the additive is directly put into the mixing pot for dry mixing, and the mixing time can be increased by 2-3 seconds.

2. Add hot asphalt and continue to stir, and the mixing time can be relatively increased.

3. The quality control, storage and transportation of the finished mixture are carried out according to the conventional mixture.

Storage environment

ventilated and dry, away from fire and light.

- Previous:

- Next: Basalt Mineral Fiber