Belonging category: Asphalt Fibers and Additives

Release time: 08-07-2023

Click count: 738

Product Details

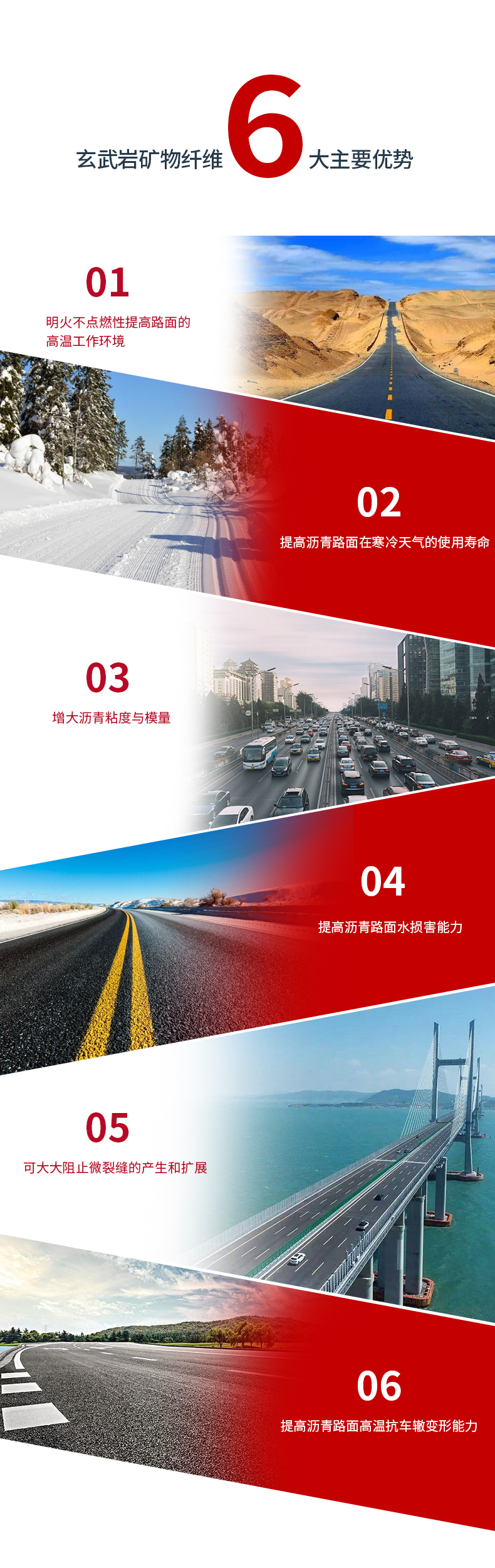

Basalt Mineral Fiber 玄武岩矿物纤维

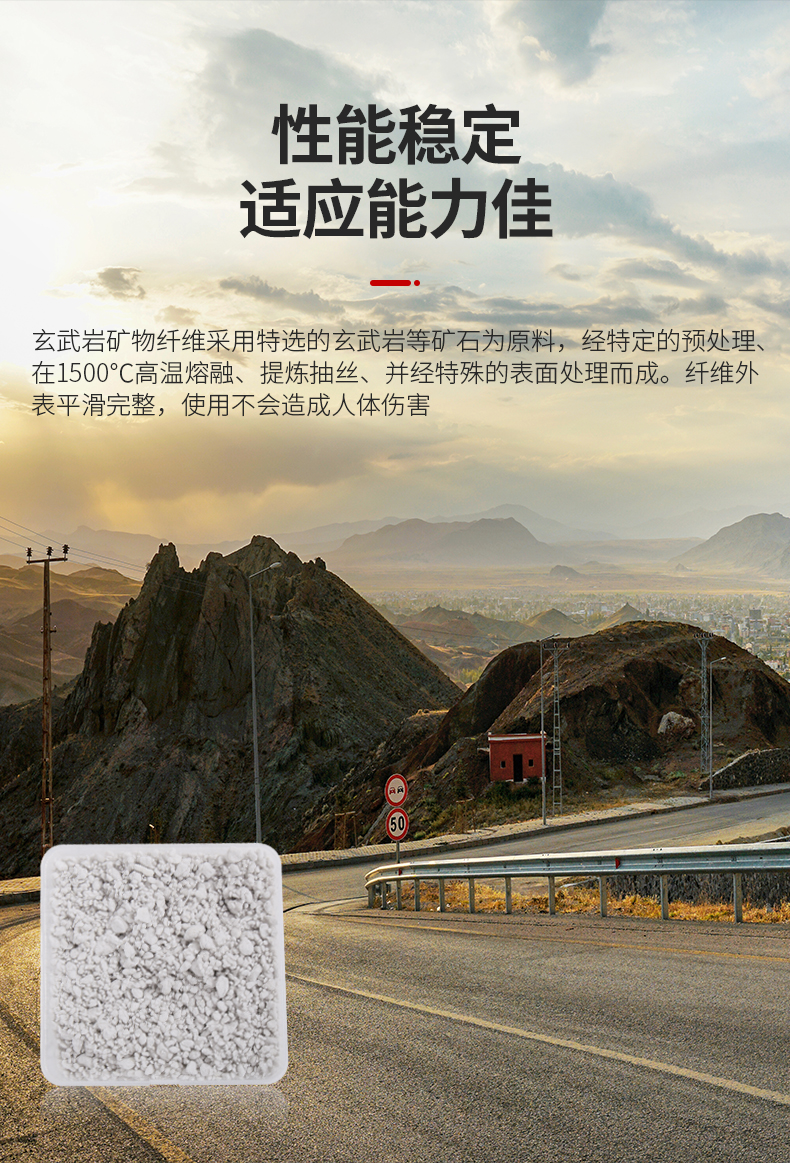

Stable performance and good adaptability.

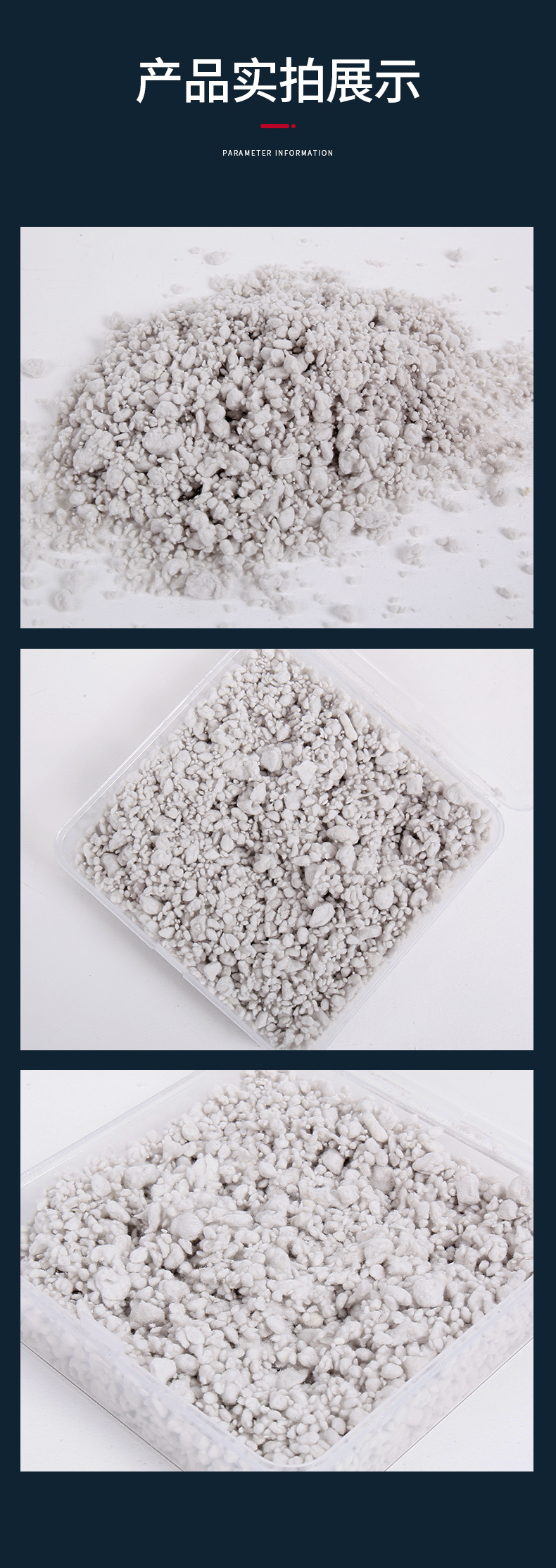

Basalt mineral fiber is made of specially selected basalt and other minerals as raw materials, and is made through specific pretreatment, high temperature melting at 1500℃, refining and spinning, and special surface treatment. The fiber surface is smooth and complete, and will not cause harm to the human body when used.

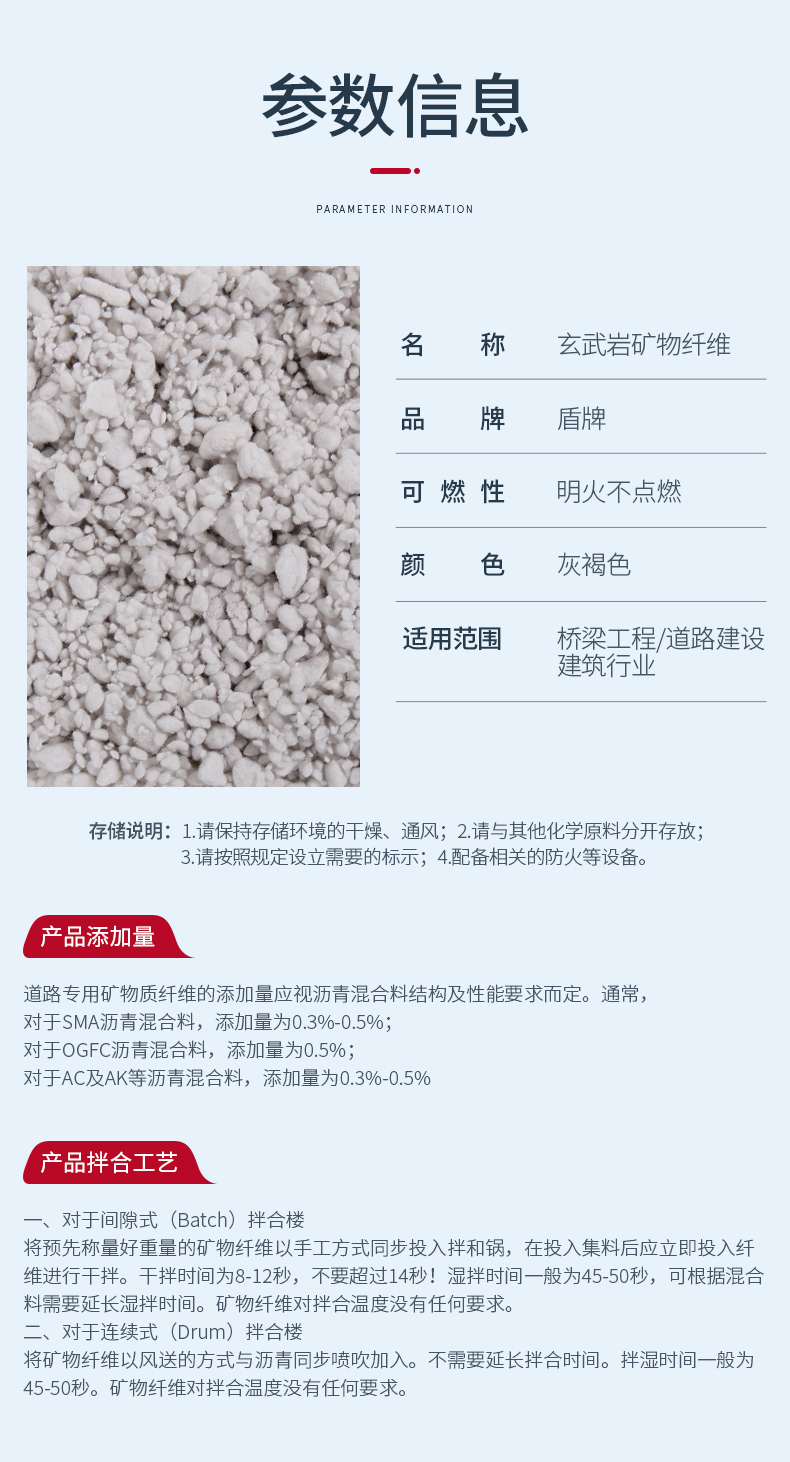

Technical parameters:

Density (g/m³): 2.50-3.50

Tensile strength (MPa): 2500-3500

Elastic modulus (GPa): 80-120

Elongation at break (%): 3.2

Maximum operating temperature (℃): 600

Strength retention rate for 1 hour at 400℃: about 82%.

Addition amount

The addition amount of road-specific mineral fiber should be determined according to the structure and performance requirements of the asphalt mixture. Usually,

For SMA asphalt mixture, the addition amount is 0.3%-0.5%.

For OGFC asphalt mixture, the addition amount is 0.5%.

For AC and AK asphalt mixtures, the addition amount is 0.3%-0.5%.

Product mixing process

1. For the batch mixing plant, the pre-weighed mineral fiber is manually added to the mixing pot simultaneously. After the aggregate is added, the fiber should be added immediately for dry mixing. The dry mixing time is 8-12 seconds, not more than 14 seconds! The wet mixing time is generally 45-50 seconds, and the wet mixing time can be extended according to the needs of the mixture. Mineral fiber has no requirements for mixing temperature.

2. For the continuous (Drum) mixing plant, the mineral fiber is blown in synchronously with the asphalt by air delivery. There is no need to extend the mixing time. The wet mixing time is generally 45-50 seconds. Mineral fiber has no requirements for mixing temperature.

Storage environment:

ventilated and dry, away from fire and light.

- Previous: Anti-rutting agent

- Next: Flocculent Lignin