Belonging category: Asphalt Fibers and Additives

Release time: 08-07-2023

Click count: 707

Product Details

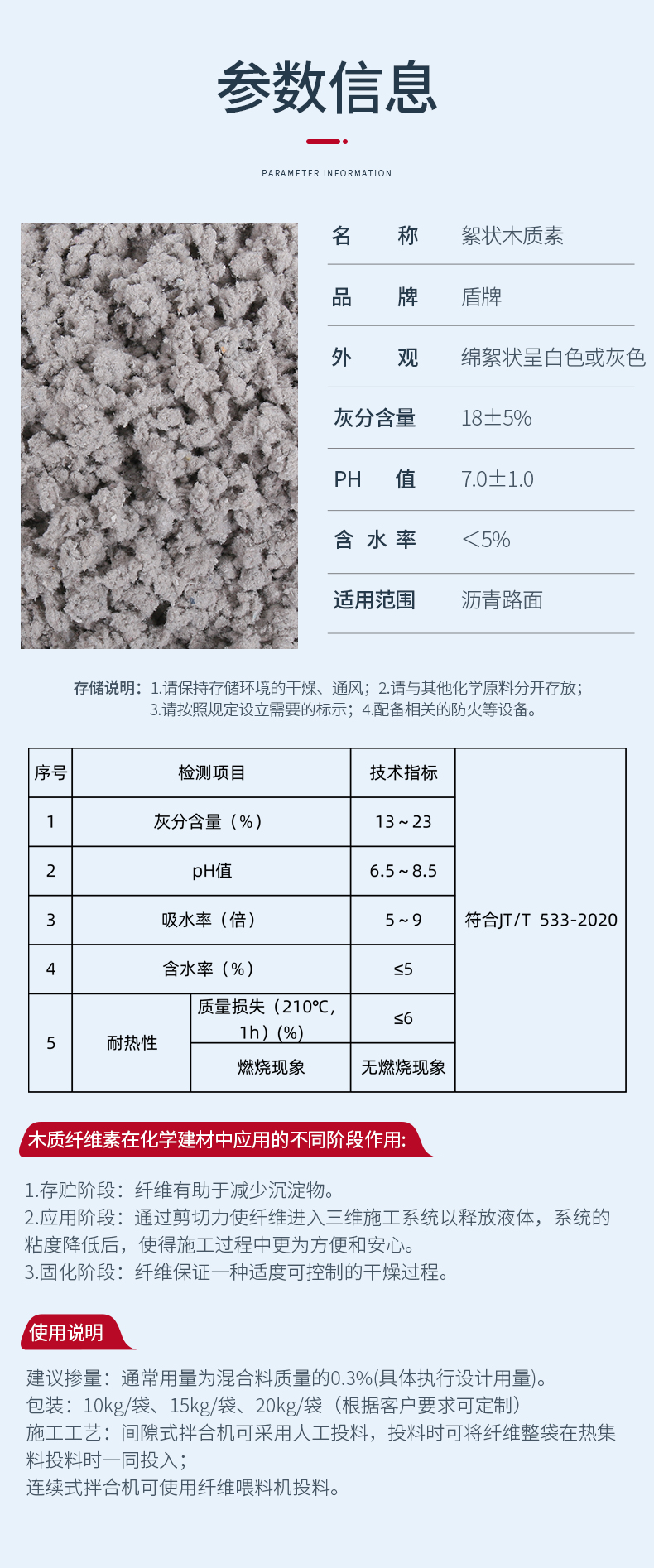

Flocculent lignin fiber 絮状木质素纤维

Lignin fiber is an organic fiber obtained by chemical treatment of natural wood. It has a cotton-like appearance and is white or grayish white. It is screened, split, treated at high temperature, bleached, chemically treated, neutralized, and screened into fibers of different lengths and thicknesses to meet the needs of different application materials. Because the treatment temperature is as high as 250°C, it is a very stable substance chemically under normal conditions. It is not corroded by general solvents, acids, and alkalis. It has excellent qualities of being non-toxic, odorless, pollution-free, and non-radioactive. It does not affect the environment and is harmless to the human body. It is a green and environmentally friendly product, which is not available in other mineral fibers. The fiber microstructure is band-shaped, curved, uneven, porous, and flat at the intersection. It has good toughness, dispersibility, and chemical stability, strong water absorption capacity, and excellent thickening and crack resistance.

Parameters:

Appearance: white or gray in cotton-like form

Oil absorption rate: not less than 5 times the mass of the fiber itself

Ash content: 18±5%

PH value: 7.0±1.0

Moisture content: <5%

Main functions

Widely used in asphalt roads, concrete, mortar, gypsum products, wood pulp sponge and other fields, it has good effects on preventing coating cracking, improving water retention, improving production stability and construction suitability, increasing strength, and enhancing adhesion to the surface. Its technical functions are mainly: thixotropy, protection, absorption, carrier and filler. In pavement paving, fiber stabilizer uses lignin fiber, which is formed into cotton-like fiber or granular fiber by the factory.

SMA characteristics of road fiber

Anti-skid and wear-resistant, anti-fatigue, and anti-high temperature rutting.

Extend the service life of asphalt pavement and reduce maintenance costs.

Improve the tensile and bonding strength of asphalt pavement

No restrictions on the properties of aggregates.

When paving continuously, the pavement has high flatness and good joints.

Applicable to various forced mixers.

Has good drainage.

Reduces noise and meets environmental protection requirements.

The price is lower than similar products.

Usage Instructions

Recommended dosage: Usually 0.3% of the mass of the mixture, the specific design dosage shall be implemented.

Construction process

Intermittent mixers can be fed manually, and the whole bag of fiber can be fed together with the hot aggregate; continuous mixers can be fed with fiber feeders.

- Previous: Basalt Mineral Fiber

- Next: Granular Lignin Fiber