Belonging category: Asphalt Fibers and Additives

Release time: 08-07-2023

Click count: 705

Product Details

Granular Lignin Fiber 颗粒状木质素纤维

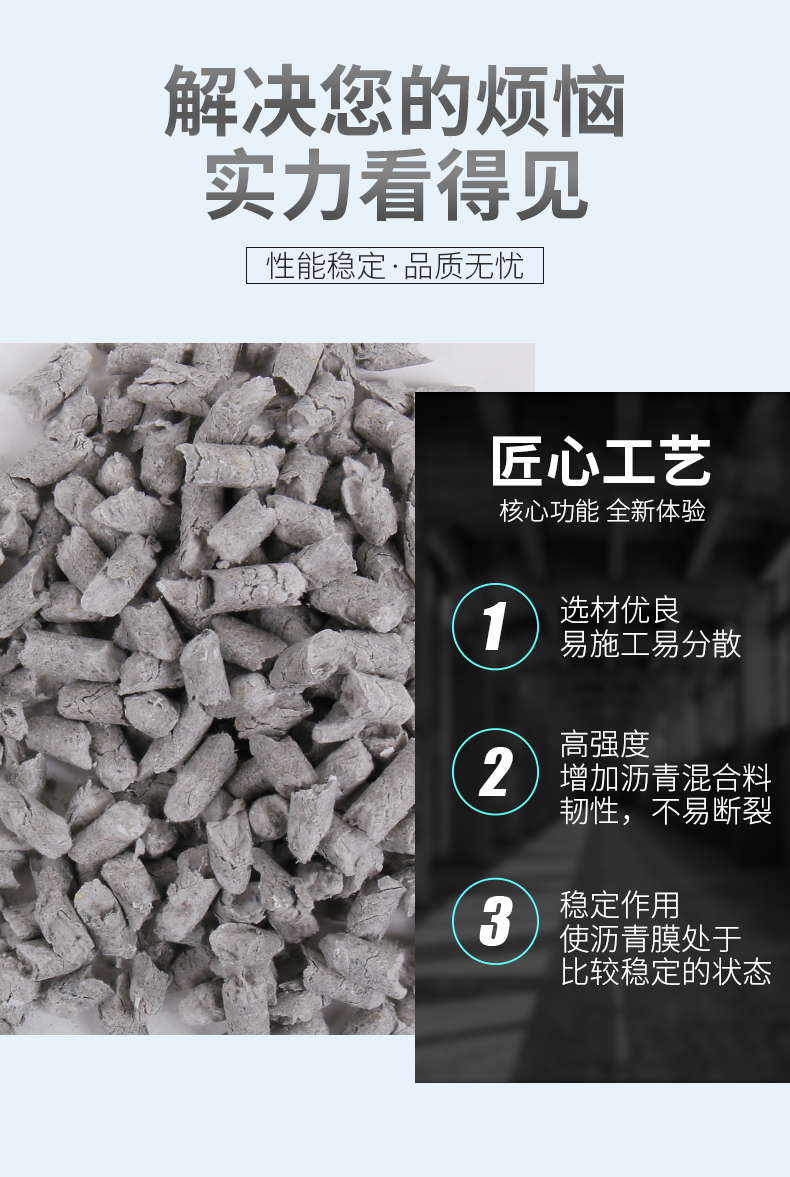

It is made of high-quality, high-purity flocculent fibers through physical action.

The main mechanism is that the fibers make the asphalt firmly form an asphalt film on the surface of the aggregate; and due to the action of the fibers, the asphalt film becomes thicker, thereby greatly improving the anti-aging ability of the asphalt layer and greatly extending its service life.

Road fiber is suitable for SMA asphalt pavement, fiber-reinforced asphalt pavement, open-graded or permeable asphalt pavement, cement pavement cover, and permeable asphalt mixture.

Performance parameters

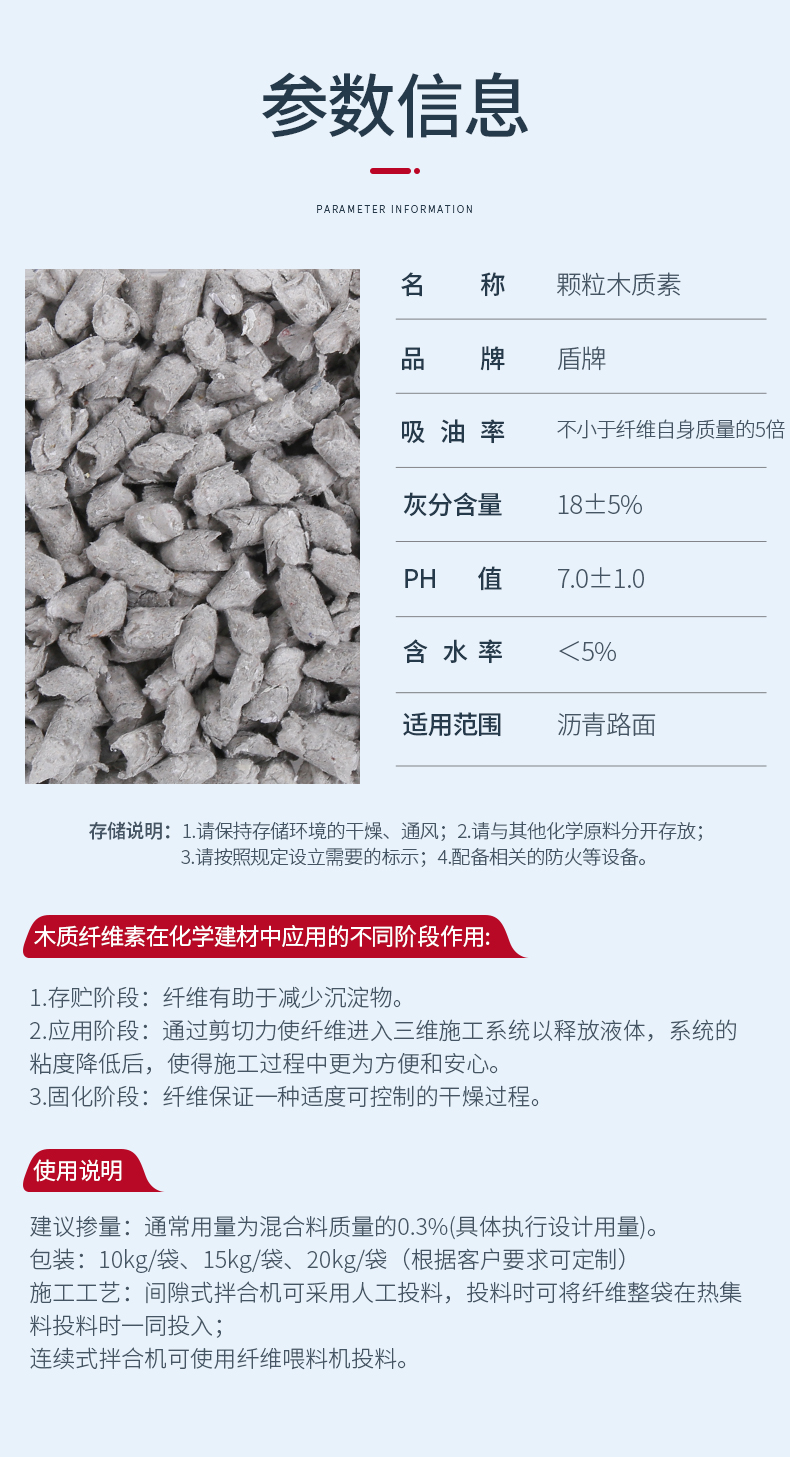

Appearance: granular fiber

Oil absorption rate: not less than 5 times the mass of the fiber itself

Ash content: 18±5%

PH value: 7.0±1.0

Moisture content: <5%

The fibers form a three-dimensional network in the asphalt mixture. At low temperatures, it has a certain degree of anti-cracking effect.

Fibers stabilize asphalt membranes. At high temperatures, the inner space of the fiber absorbs part of the thermally expanded asphalt, preventing it from becoming free asphalt, thus preventing oil spillage and improving high temperature stability.

The fiber stabilizer in the asphalt mixture absorbs more asphalt through the adsorption of asphalt on the fiber surface. It forms a thicker asphalt structural film on the aggregate surface and improves the durability of the mixture. During the production, transportation and paving process, asphalt will flow to the bottom of the mixture due to its own gravity. After fiber stabilizer is added during the mixing process, the fibers will firmly hold the asphalt with its unique three-dimensional network structure and prevent the dripping and segregation of asphalt. And the fiber has extremely strong stiffening properties and can greatly strengthen asphalt mortar. This greatly improves the high and low temperature stability of the asphalt mixture.

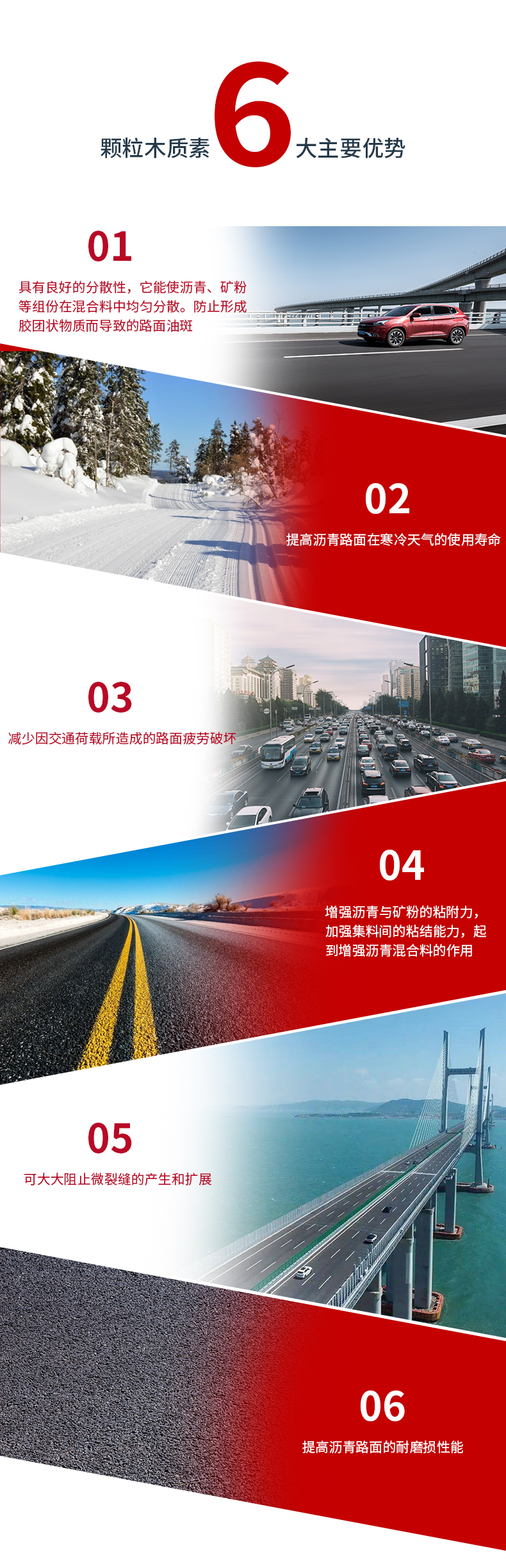

Fiber stabilizer has good dispersibility, which can make asphalt, mineral powder and other components evenly dispersed in the mixture. Prevents oil spots on the road caused by the formation of gelatinous substances.

Fiber can increase the adhesion between asphalt and mineral powder, greatly increase the viscosity of asphalt mastic, strengthen the bonding ability between aggregates, and play the role of strengthening the asphalt mixture.

Usage Instructions

●Recommended dosage: Usually 0.3% of the mass of the mixture (specific design dosage).

●Construction process

Intermittent mixers can be fed manually, and the fiber bag can be fed together with the hot aggregate. Continuous mixers can be fed with fiber feeders

- Previous: Flocculent Lignin

- Next: