Belonging category: Cement Concrete Fibers

Release time: 08-07-2023

Click count: 729

Product Details

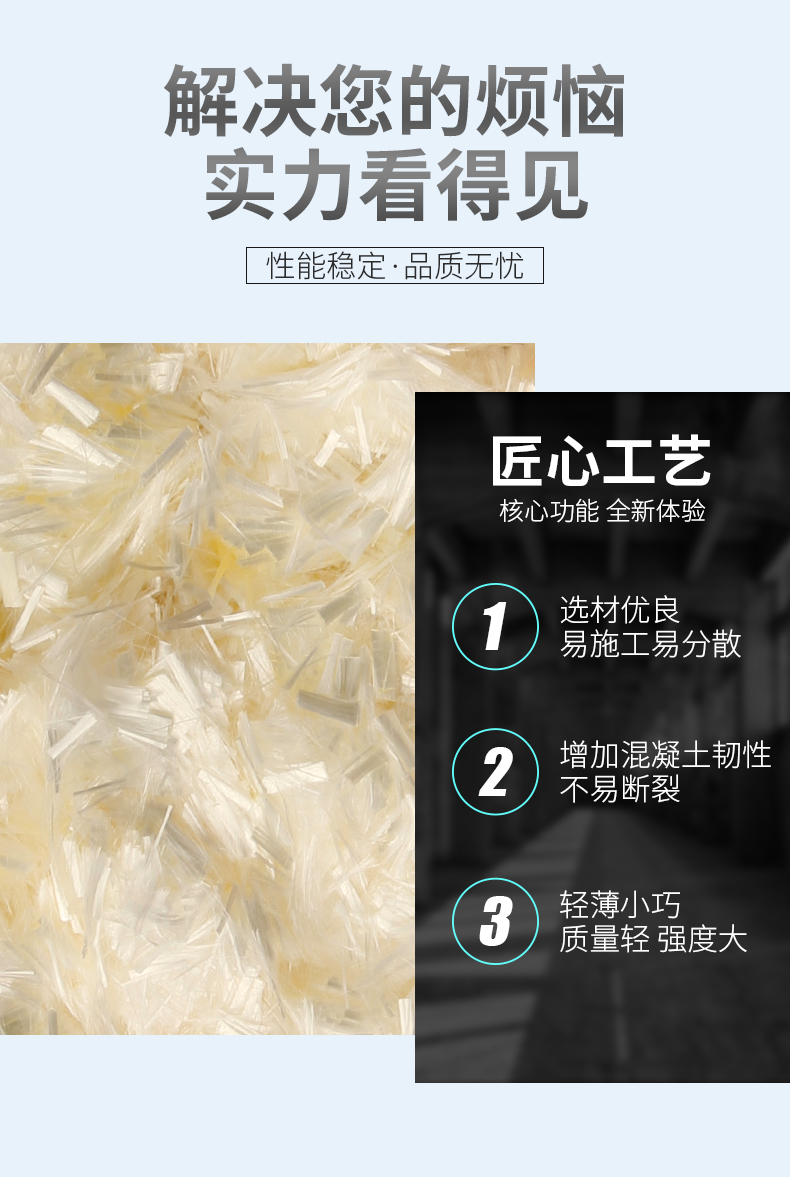

Polyacrylonitrile mono filament fiber (PAN fiber) 聚丙烯腈纤维

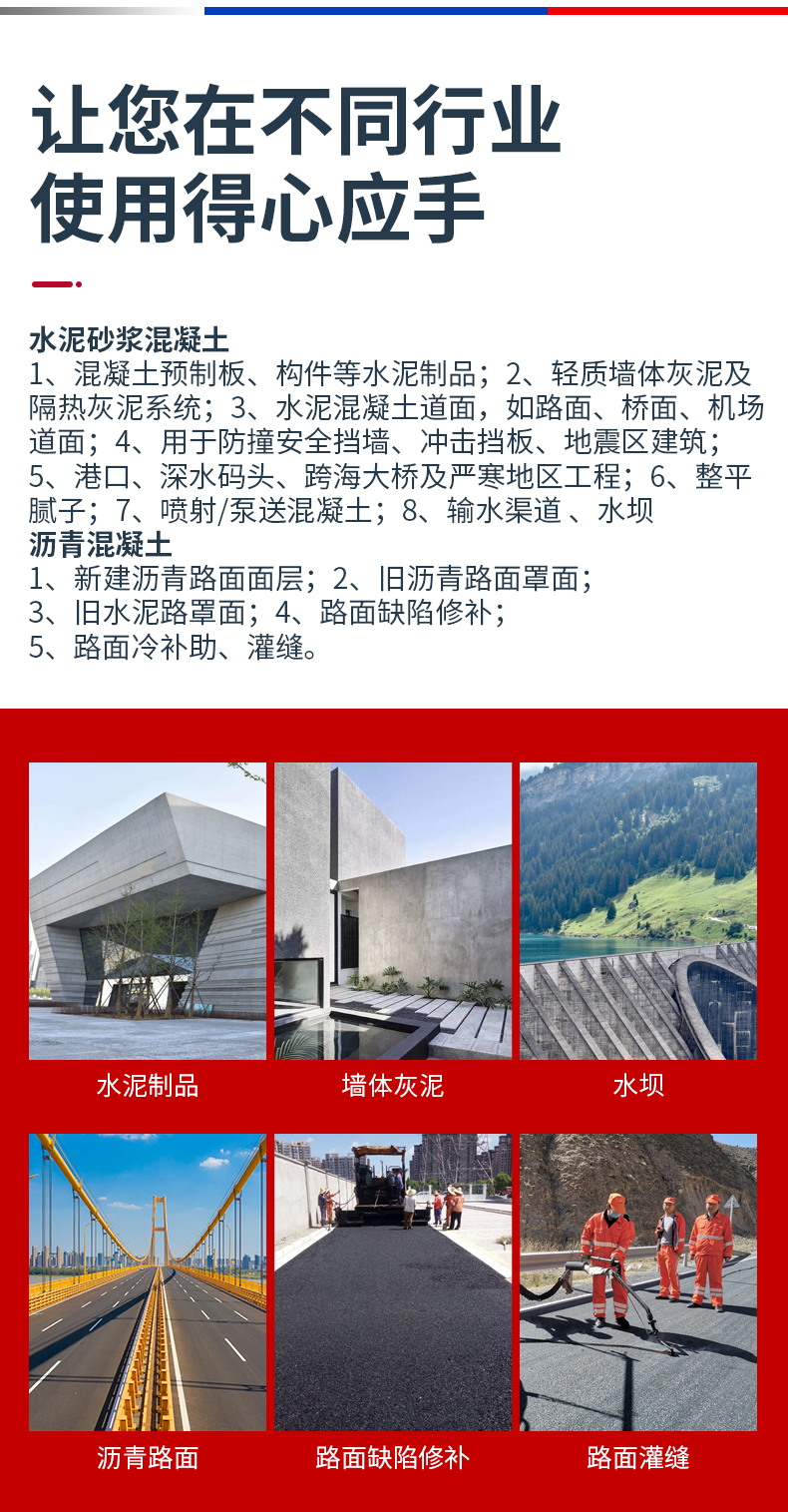

Applicable to: tunnels, airports, bridges, pools, water conservancy projects, advanced highways, high-speed railways, ports and docks, basements, rooftops, etc.

The role of polyacrylonitrile fiber in concrete

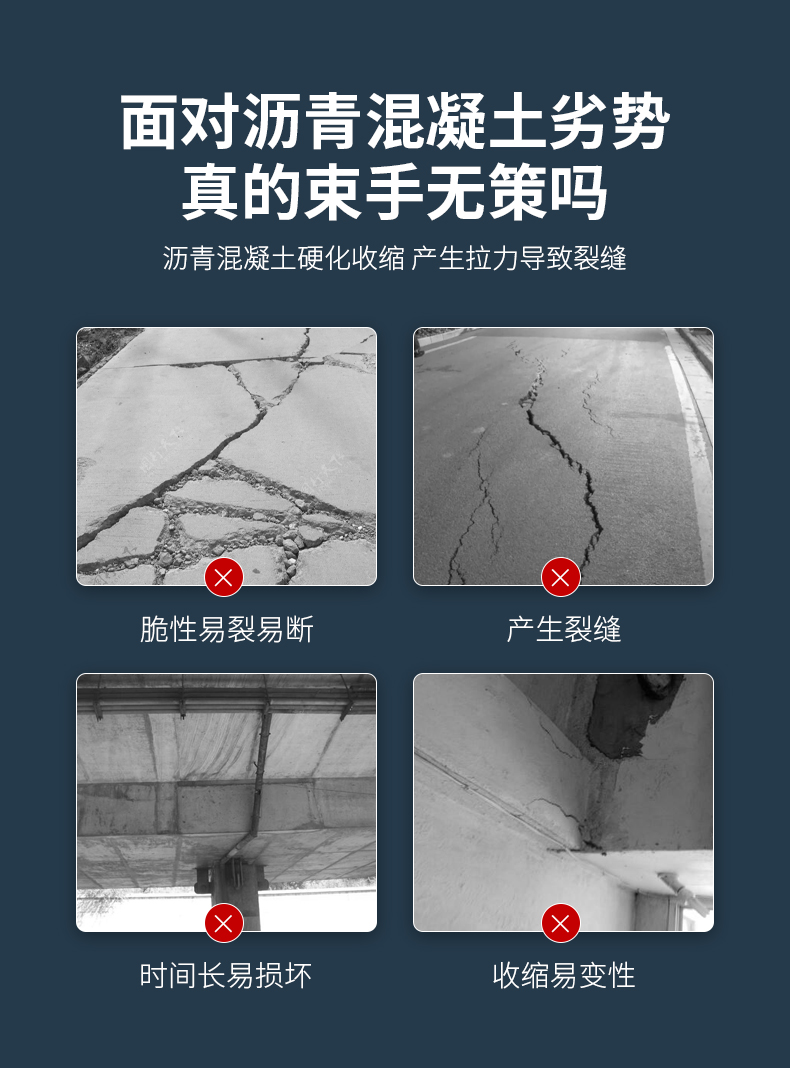

1. Effectively improve the crack resistance of cement concrete. It has good adhesion with cement, can support aggregates, reduce water seepage and prevent settlement cracks. Adjust the water content to avoid shrinkage cracks caused by too fast evaporation of water.

3. Regulate the temperature stress caused by hydration heat release and external temperature changes in the concrete to reduce the crack level.

2. Improve the impermeability and frost resistance of cement concrete and increase its durability: Fiber greatly reduces the size of capillaries in concrete and the number of connected capillaries, effectively improving the frost resistance and impermeability of concrete. The number of frost resistance of fiber concrete can reach 600 times.

3. Reduce the brittleness of concrete and ensure the strength of cracked concrete.

4. Improve the high temperature stability of asphalt concrete.

5. Improve the low temperature crack resistance, tensile strength and shear strength of asphalt concrete.

6. Improve the durability and fatigue resistance of asphalt concrete.

7. Improve the water stability and flexibility of asphalt concrete.

8. Improve the wear resistance and spalling resistance of asphalt concrete.

9. Resist reflective cracks.。

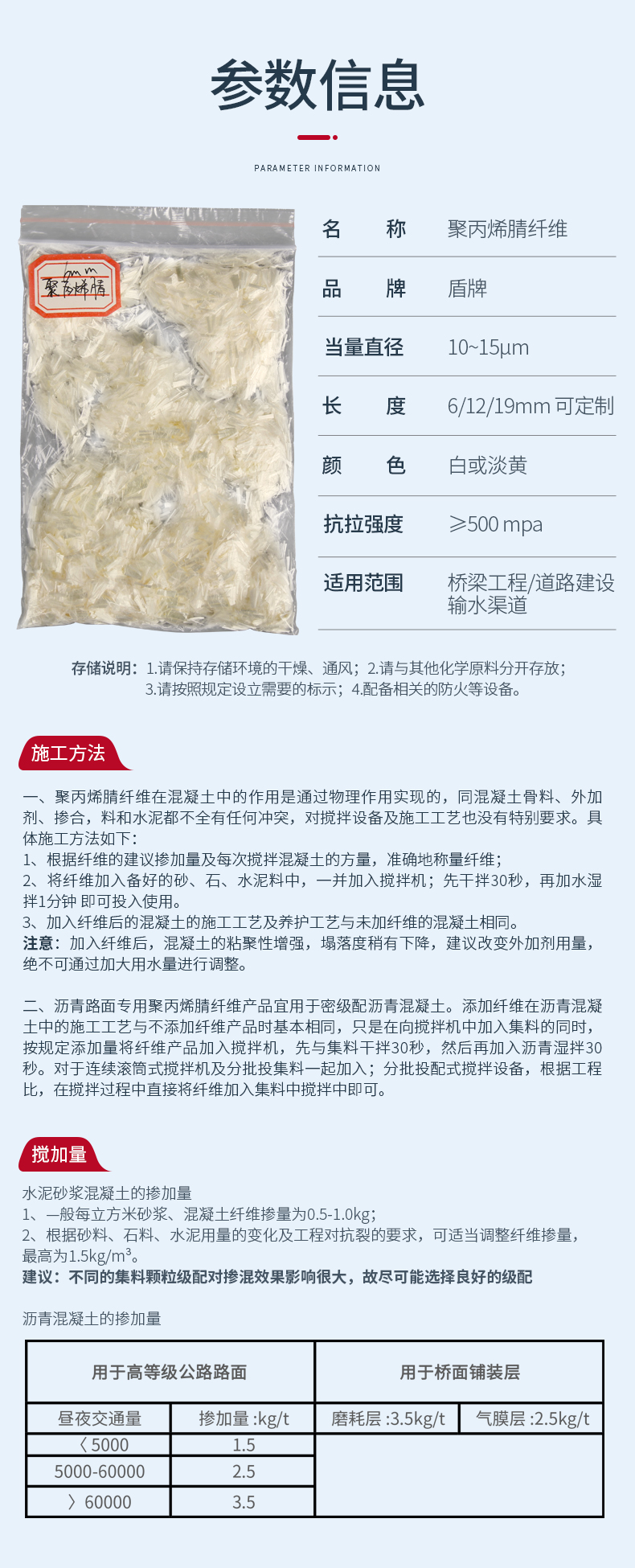

Paramenters:

Density (dtex): 1.9-3.8

Length (mm): 6, 12, 19

Diameter (um): 15-30

Color: bright, light yellow or white

Density (g/cm3): 1.18

Elastic modulus (G): 17

Number of fibers per kilogram (6mm): 800-900 million

Elongation (%): 14-20

Tensile strength (MPa)>900

Acid resistance: good

Alkali resistance: good

Light resistance: good - the best light resistance fiber except fluorine-containing fiber

Heat resistance: good - carbon fiber raw yarn can withstand 240℃ high temperature for a short time without melting

Hydrolysis resistance: good

Construction process:

ONE.

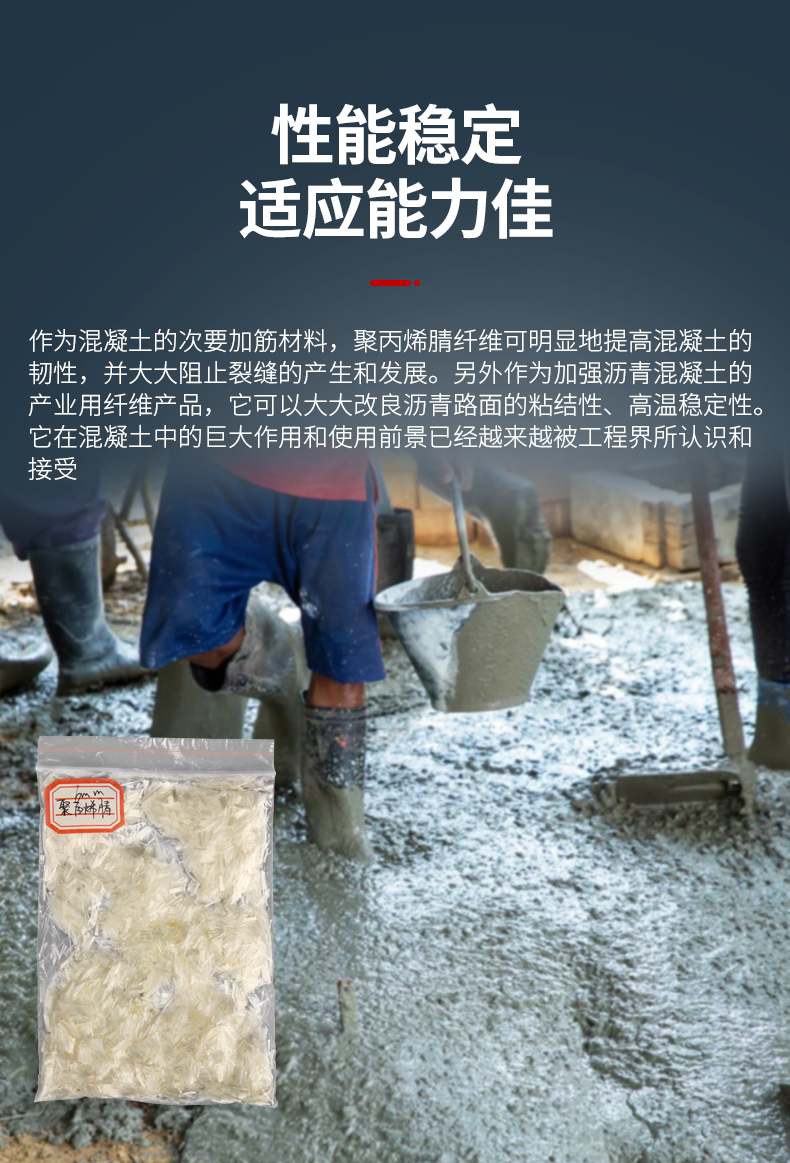

The role of polyacrylonitrile fiber in concrete is achieved through physical action. It does not conflict with concrete aggregates, admixtures, admixtures and cement, and has no special requirements for mixing equipment and construction technology. The specific construction method is as follows:

1. Accurately weigh the fiber according to the recommended fiber addition amount and the volume of concrete mixed each time.

2. Add the fiber to the prepared sand, stone and cement materials and add them to the mixer; dry mix for 30 seconds, then add water and wet mix for 1 minute before putting it into use.

3. The construction process and maintenance process of concrete with fiber added are exactly the same as those of concrete without fiber added.

Note: After adding fiber, the cohesiveness of concrete is enhanced and the slump is slightly reduced. It is recommended to change the amount of admixture, and it must not be adjusted by increasing the amount of water.

TWO.

Polyacrylonitrile fiber products for asphalt pavement are suitable for dense graded asphalt concrete. The construction process of adding fiber to asphalt concrete is basically the same as that without adding fiber products, except that while adding aggregate to the mixer, the fiber product is added to the mixer according to the specified addition amount, first dry-mixed with aggregate for 30 seconds, and then wet-mixed with asphalt for 30 seconds. For continuous drum mixers and batch-feeding aggregates, add them together; for batch-feeding mixing equipment, according to the engineering ratio, directly add the fiber to the aggregate during the mixing process.

Addition amount

I. Addition amount of cement mortar concrete

1. Generally, the fiber addition amount per cubic meter of mortar and concrete is about 1.0kg.

2. According to the changes in the amount of sand, stone, and cement and the requirements of the project for crack resistance, the fiber addition amount can be appropriately adjusted, with the maximum addition amount being 1.5kg/m3.

Suggestion: Different aggregate particle grading has a great influence on the mixing effect, and a good grading should be selected as much as possible.

II. Addition amount of asphalt concrete:

For high-grade highway pavement, the addition amount is 1.5-3.5 KG/ TON.

Used for bridge deck pavement 2.5-3.5 KG/ TON

Storage environment:

Ventilated and dry, away from fire and light.

- Previous:

- Next: Polypropylene Fiber (PP Fiber)