Belonging category: Cement Concrete Fibers

Release time: 08-07-2023

Click count: 511

Product Details

Polypropylene monofilament fiber (PP fiber) 聚丙烯单丝纤维

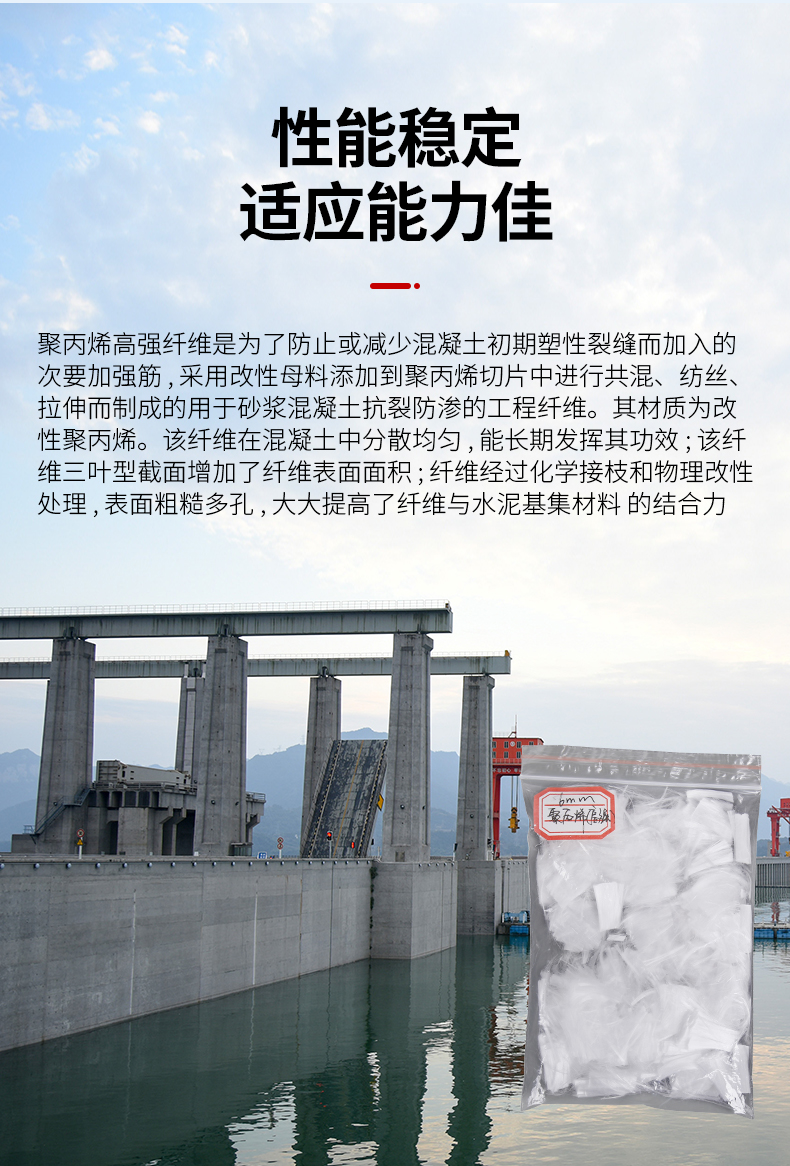

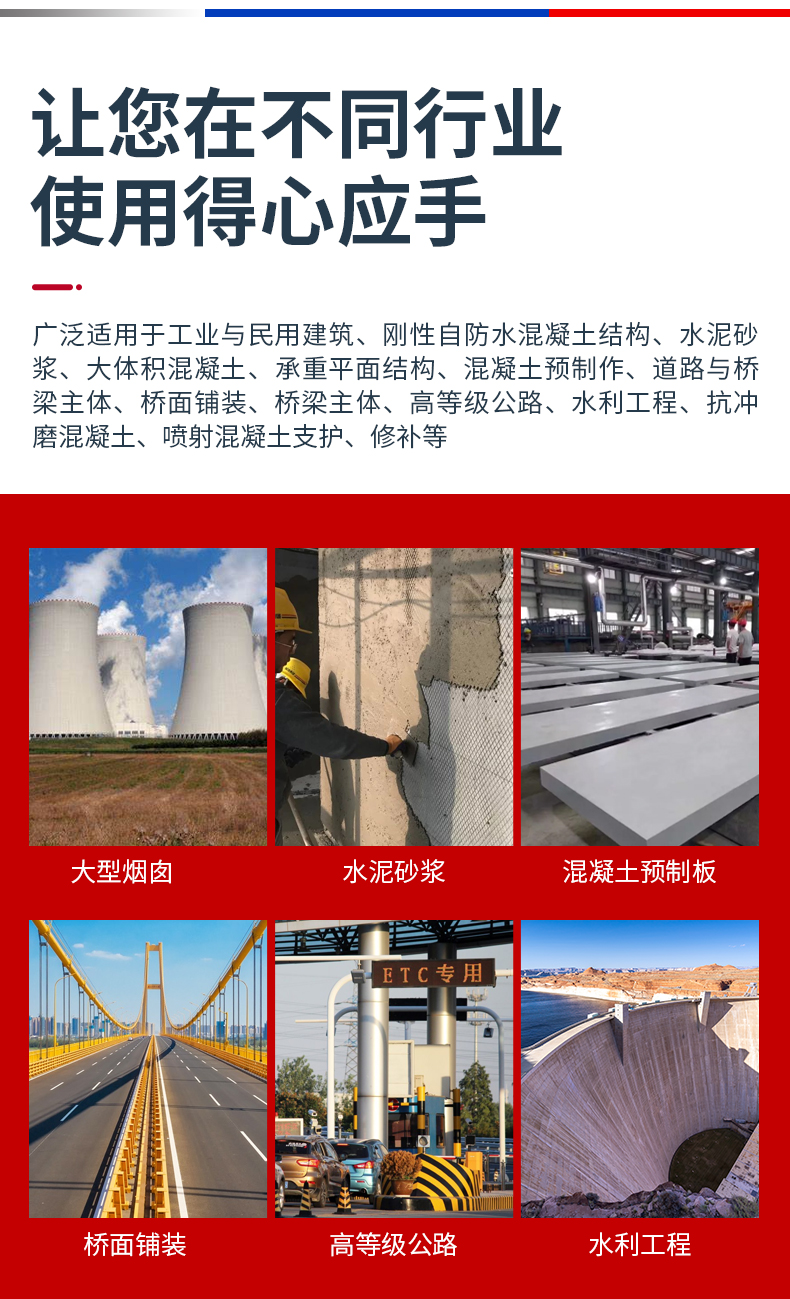

Applied in: tunnels, airports, bridges, pools, water conservancy projects, high-speed highways, high-speed railways, ports, basements, rooftops, etc.

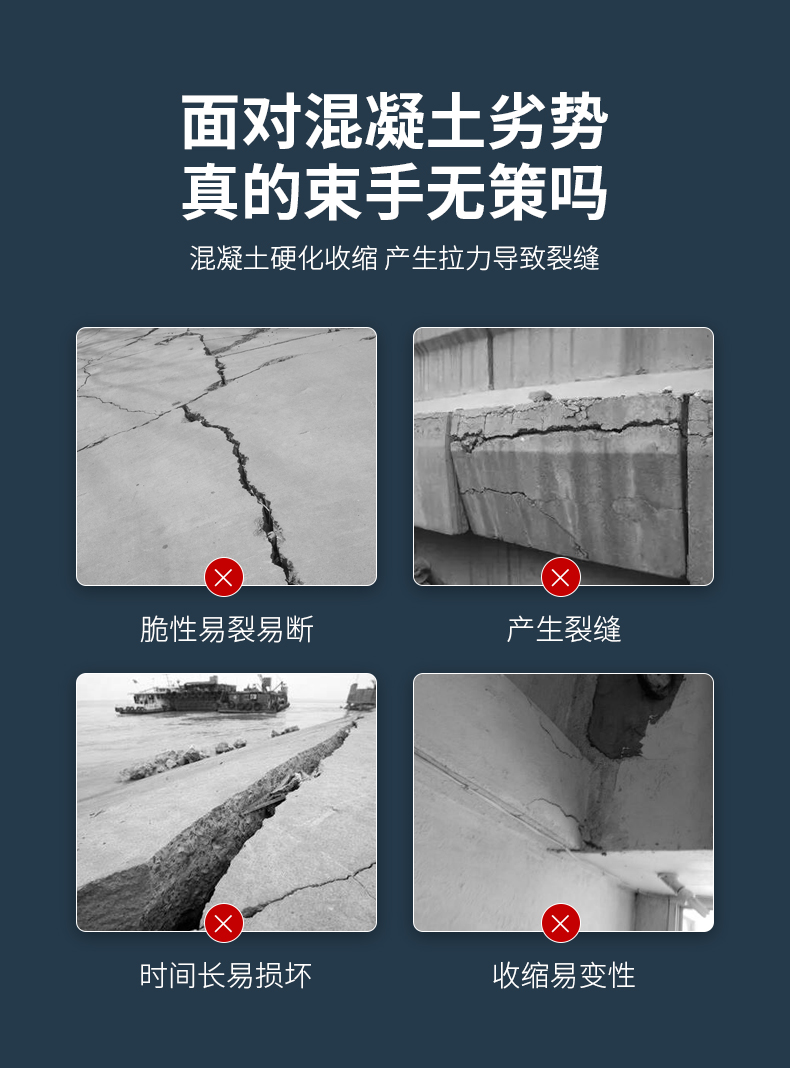

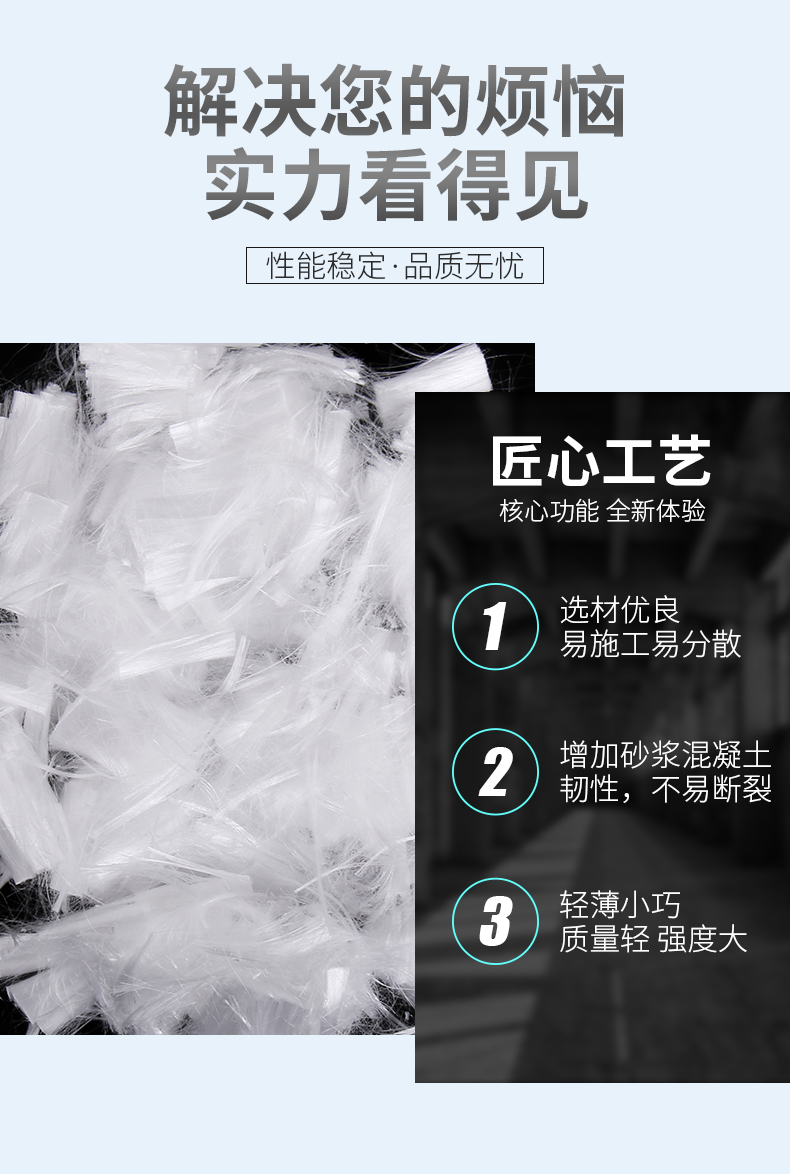

Function: Reduce the initial plastic cracks of concrete and is the secondary reinforcement of concrete. The fiber is evenly dispersed in the concrete and can exert its effect for a long time. After chemical grafting and physical modification, the surface is rough and porous, which greatly improves the bonding force between the fiber and the cement-based material.

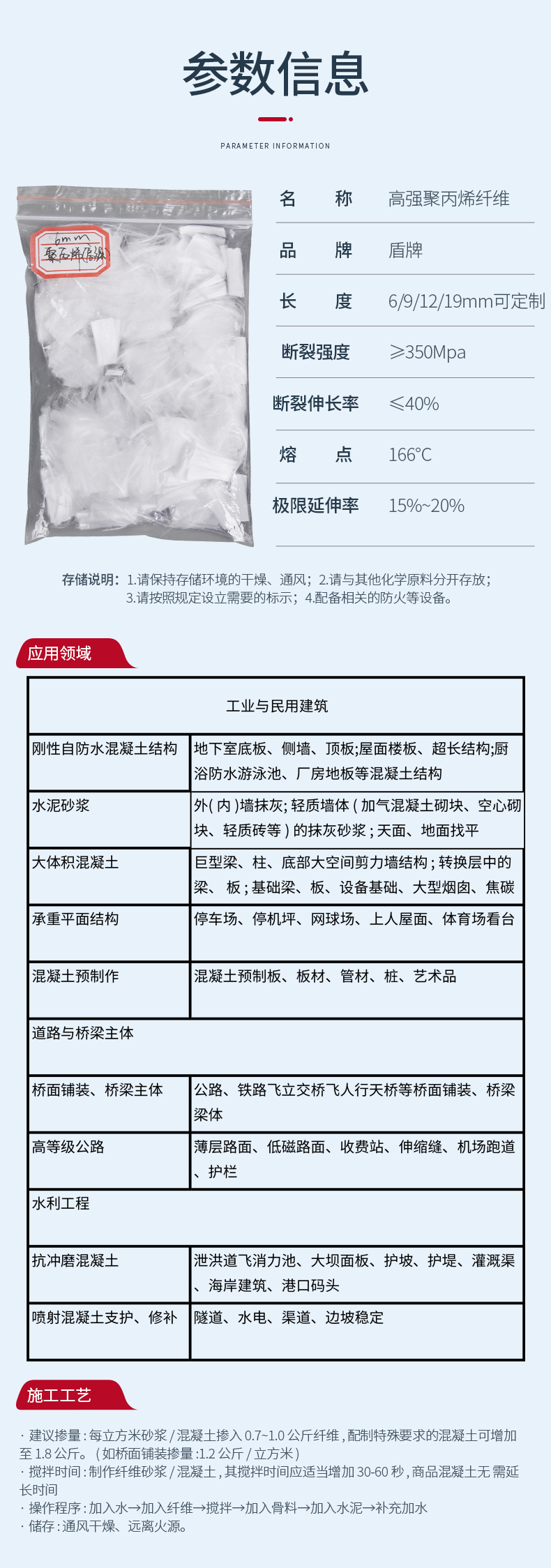

Technical parameters:

Density: 0.91 g/m3

Elastic modulus>3500

Tensile strength: 350-600MPa

Elongation at break>10%

Diameter 25-40 microns.

Dispersibility: good

Water absorption: no water absorption

Acid and alkali resistance: strong

Melting point: 160-170℃

Construction process:

Suggested dosage: generally 1.0KG/cubic meter of concrete; concrete with special requirements can be increased to 1.2-1.8KG/cubic meter.

Mixing time: Appropriately increase by 30-60 seconds. Commercial concrete does not need to extend the time.

Operation procedure: add water, add fiber, mix, add aggregate, add cement, add water.

Storage environment: ventilated and dry, away from fire and light.

- Previous: Polyacrylonitrile Fiber (PAN Fiber)

- Next: Basalt fiber

Recommended Products